ALiEn2 is the most feature-rich plunger lift controller in its class. Patented optimization algorithms achieve maximum production with minimal operator intervention. Use as a simple well intermitter or in conjunction with a plunger arrival sensor to optimize production. Protect your well by using a line pressure device to shut in on high line pressure. Log your plunger’s mileage with Plunger Tracking, and use Vent Tracking to keep tabs on vent time.

ALiEn2‘s standard Modbus communication port enables remote monitoring and control, and is pre-configured to work with several popular SCADA solutions.

ALiEn2 can also be configured to work with your internal SCADA system. No SCADA? ALiEn2 is fully functional and accessible right on site.

ALiEn2 and ALiEn2 Expert come certified to the highest and most up-to-date safety standards available, providing unlimited safe installation locations. Features such as Fast Velocity, Dangerous Velocity, and a variety of configurable alarms protect your well head equipment and prevent accidents.

Brochure Case Study

Features and Benefits

- Class I, Zone 0 (Div 1) Certified

- -40°F to +160°F Operation

- 8+ Months of Battery Standby**

- Numeric/Navigation Interface

- Operate up to 3 Valves**

- RS-485 Modbus Communications

- Adaptive Seeking Velocity Optimization™

- Pressure Optimization

- Flexible Connector/Solenoid Locations

- Universal Mounting

- Type 4 Powder Coated Steel Enclosure

- Locking Door

Documentation and Software

**Expert Model Only

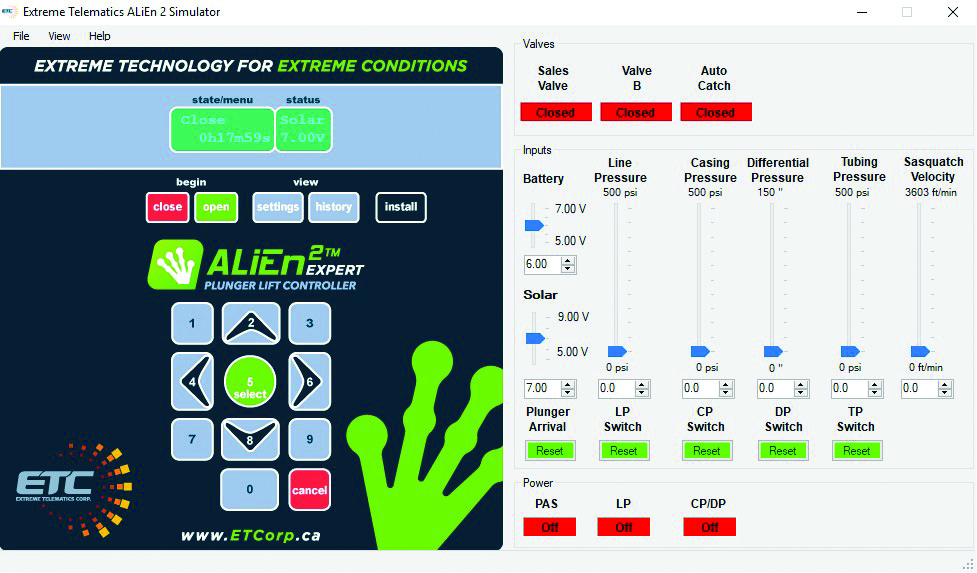

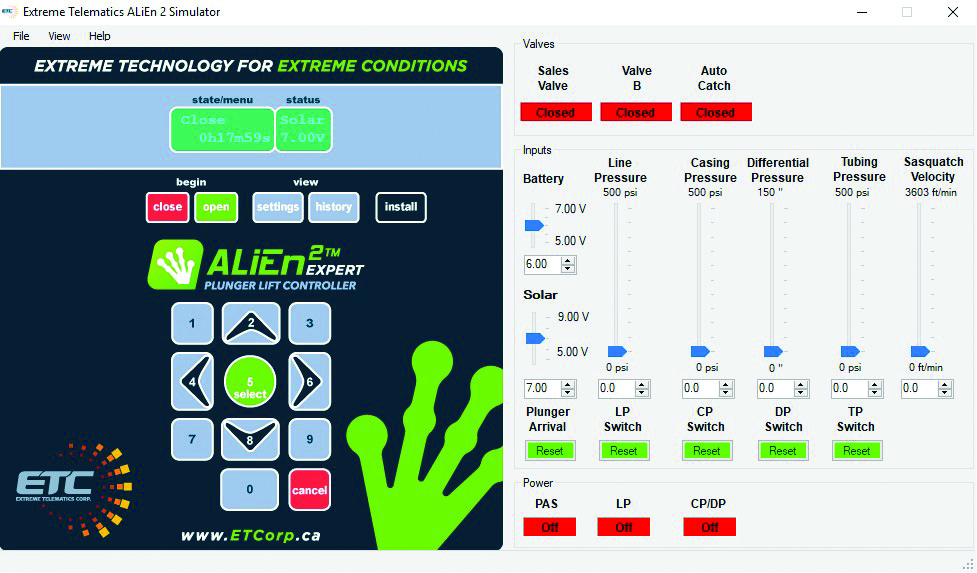

ALiEn2 Interactive Simulator

Download Simulator

The ALiEn2 Plunger Lift Controller Simulator is built off of the same software that is running on the controller. Use it for training, demonstrations, troubleshooting and more. Conveniently switch between the available models of the ALiEn2 and see a dynamic view of the available devices and menu items. The inside door instruction label, quick start guide, user’s manual, and Modbus guide are all conveniently built in so you have everything in one place.

Adaptive Seeking Velocity Optimization™

This patented* algorithm reduces the need for operator intervention by making automatic adjustments that are proportional to the current flow/close time. When Adaptive Seeking Velocity Optimization™ is used with a plunger arrival sensor such as Cyclops, ALiEn2 reacts to the average velocity of the plunger, making proportionate changes to the amount of Close and Afterflow time for the well. The user specifies a Target Rise Velocity, which ALiEn2 then works to achieve. For best results, use a Sasquatch Plunger Velocity Sensor in conjunction with Adaptive Seeking Velocity Optimization™ to maximize production using real time Surface Velocity. ALiEn2 is the first plunger lift controller capable of optimizing on Surface Velocity; a standard feature in the ALiEn2 Expert model, available as an upgrade for the ALiEn2.

Pressure Optimization

Use a combination of Line Pressure, Tubing Pressure, Casing Pressure** and Differential Pressure** to optimize the well. ALiEn2 automatically adapts to use enabled devices. Optimize on Flow Rate (AGA 3 table based) when using a Line Pressure and Differential Pressure sensor.

Load Factor

Load Factor is a parameter that can be used to determine when to open a plunger lift well to rise the plunger. It is a ratio of the slug size (casing pressure – tubing pressure) to the lifting pressure (casing pressure – line pressure). It is used by a number of different control systems as a standard optimization setting and is a standard feature on the ALiEn² Expert plunger lift controller. Please note that this feature requires a pressure splitter.

*Patent Number US 9,297,238

SPECIFICATIONS

|

|

|

| Operating Temp |

-40°C to +70°C (-40°F to +160°F) |

-40°C to +70°C (-40°F to +160°F) |

| Current Draw |

Typ. – 0.5 mA, Max. – 190 mA |

Typ. – 0.5 mA, Max. – 190 mA |

| Battery |

6 V, 5 Ah |

6 V, 8 Ah |

| Valves Supported |

1-2 |

1-3 |

| Standby Time |

5+ Months*

|

8+ Months*,**

|

| Solar Panel |

6 V, 1.1 W |

6 V, 1.1 W |

| Arrival Sensor |

Cyclops, Most other vendors |

Cyclops, Sasquatch, Most other vendors |

| Other Inputs |

Line Pressure

Inputs can be dry contact switch or 0.5 V to 4.5 V sensor |

Line Pressure or Tubing Pressure, Casing Pressure or Differential Pressure

Inputs can be dry contact switch or 0.5 V to 4.5 V sensor |

| Cycle History |

Last 25 Cycles |

Last 25 Cycles |

| Daily History |

Current Day + 14 Previous Days |

Current Day + 14 Previous Days |

| Communications Interface |

2 wire RS-485 Modbus Slave |

2 wire RS-485 Modbus Slave

2 wire RS-485 Modbus Master |

| Certifications |

Class I, Zone 0, Ex/AEx ia [ia] IIB

Class I, Division 1, Groups C and D |

Class I, Zone 0, Ex/AEx ia [ia] IIB

Class I, Division 1, Groups C and D |

*Average temperatures of -20°C, 24 valve operations a day, 10 minutes a week of display-on time, and a Cyclops arrival sensor.

**Expert model.